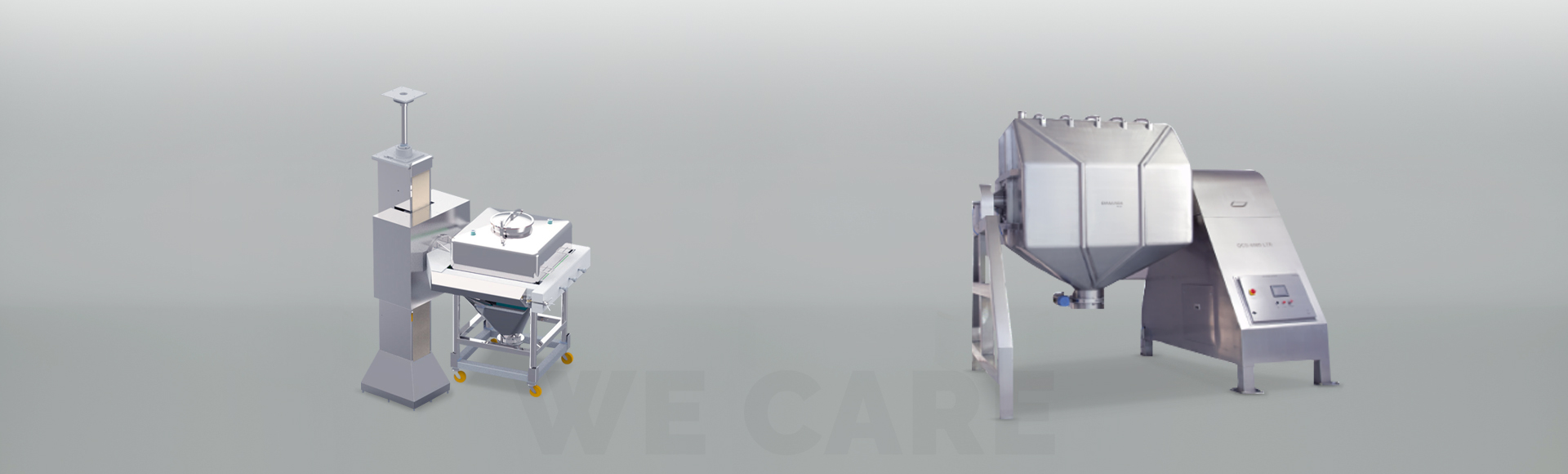

IBC Bin Blender R & D Model

This is a simple unit used for dry blending of Powder and lubrication of Granules for tablet compression. It employs the principle of tumbling of powder in a partial void to cause homogenous mixing.

As the Blender is of lower capacity one sided shaft support is used, which is directly coupled with the worm reduction gear box driven by the direct drive and the same is mounted on structure. Safety railing is provided with proximity switch. When safety railing is open during operation machine should be stop. For safety electrical operating panel mounted on machine for easy operation. Castor wheel is provided for easy mobility of the machine.

Request A Quote