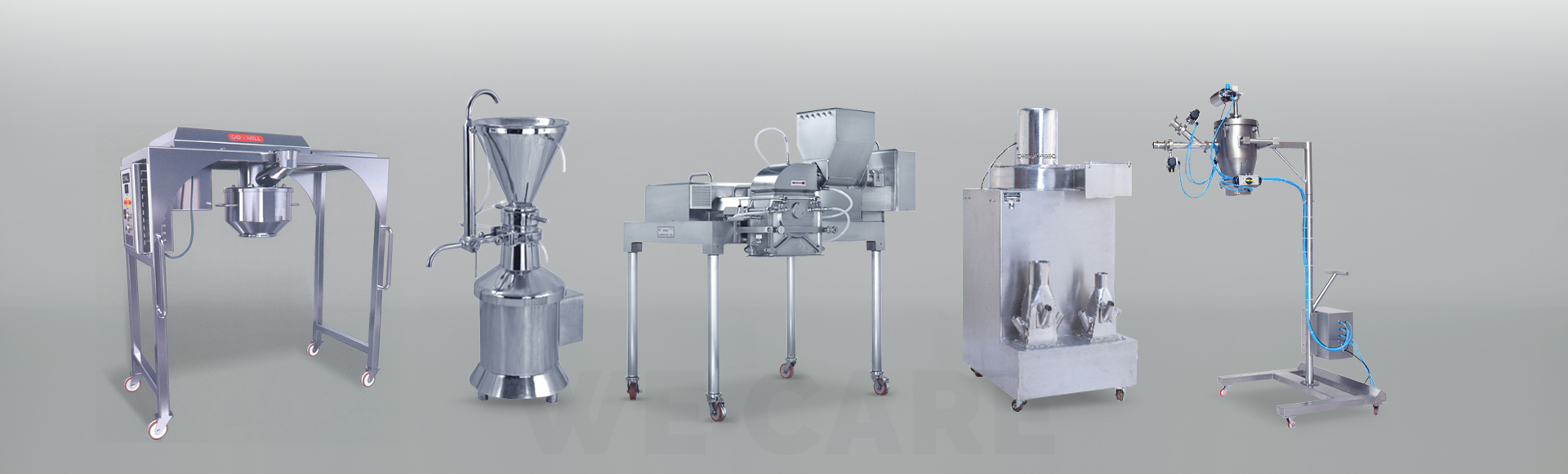

Product Description

For a non-isometric particle, the axis must be correctly aligned with respect to the place of the screen. And the center of gravity of the particle must be above the aperture at any instant. Further, the amount of material on the screen should be such that the passage of small particles is not obstructed by larger particles.

It is therefore necessary to impart horizontal rotary motion to the particle by suitable means. Care also has to be taken to ensure that such motions, particularly during dry sieving of grading operation, should not be vigorous so as to cause size reduction of particles themselves or damage to the screen.

CLIT Sieving Grading and Straining Machines was specially developed with the above design features to provide gyratory vibration. The amplitude of vibration is adjustable to suit processing needs.